Our Capabilities

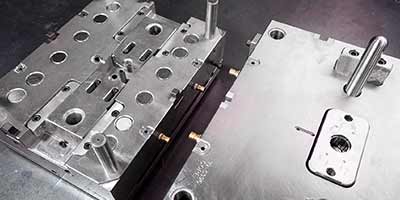

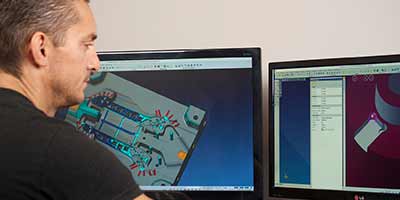

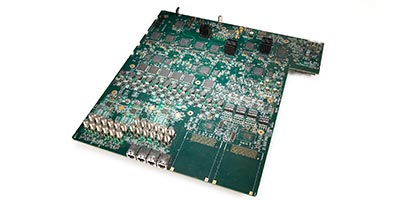

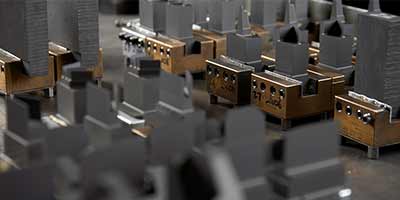

Global Design is an industry leader in injection molds, prototypes, and production. Our state-of-the-art facility features a variety of machines and equipment that we utilize to streamline the various molding and tooling processes. We specialize in plastic injection molds that are used to create quality precision parts for industries and applications of all shapes and sizes.

In addition to our in-house operations, we offer imported production injection molds and molded parts from overseas. Every product comes with a US warranty and is hand-delivered right to your doorstep. We also offer in-mold decorate trim for usage in automobile dashboards, as well as vacuum form tolling, automated trim dies, program management, mold repair, spotting and benching, and much more.

Contact us today to learn more about what the experts at Global Design can do for you.